POWER BASE

It produces more sophisticated products with more advanced technology.

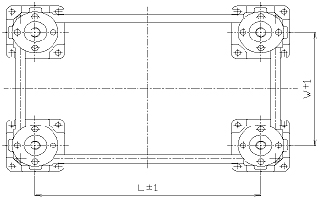

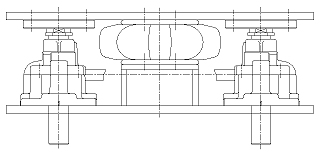

1) Check the distance between center

The distance between the centers of the power base has an allowance of ±1 mm on both sides, so even if the dimensions of the frame's mounting surface differ by about ±2 mm, assembly is still possible.

However, if the dimensions of the upper and lower surfaces are incorrect, it will create a load on the rack gear, so the positions of the centers of the upper and lower surfaces must be aligned accurately.

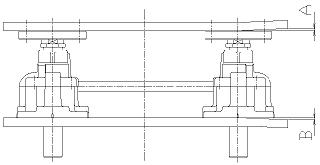

2) Caution for frame deformation

Minimize the deformation of the upper and lower frames, and if deformation occurs, the basic height at the four points should be adjusted using the fine-tuning joint at the flange.

If the adjustment is not done correctly, a load will be placed on the rack gear, which will prevent smooth operation.

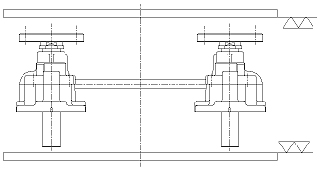

3) Machining of the mounting surface

- For more precise operation and horizontal leveling, the mounting surface of the power base should be machined before installation.

- After welding the frame structure, process the mounting surface and assemble it.

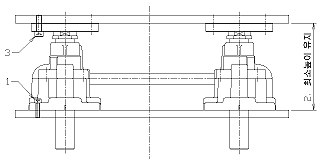

4) Flange assembly in the down position

After bolting the gearbox section of the power base, the upper frame should be bolted while in the down position as much as possible to reduce the load and vibration on the rack gear.

5) Elimination of play between the upper and lower surfaces

When using a single-acting cylinder or air spring as the driving source, the mounting surface of the power base must be machined, or a liner must be used to eliminate the play between the upper and lower surfaces before assembling the power base.

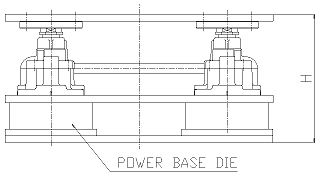

6) Precautions during the assembly of the POWRE BASE DIE

When installing the power base die to adjust the height (H), if the mounting bolts are tightened too strongly from the beginning, it may misalign the distance between the centers of the power base and create a load. Therefore, it is recommended to loosen the mounting bolts slightly, conduct an up-down test, and then tighten them for smoother operation.